Rotational Moulds

- Home

- Product

What is Rotational Moulding?

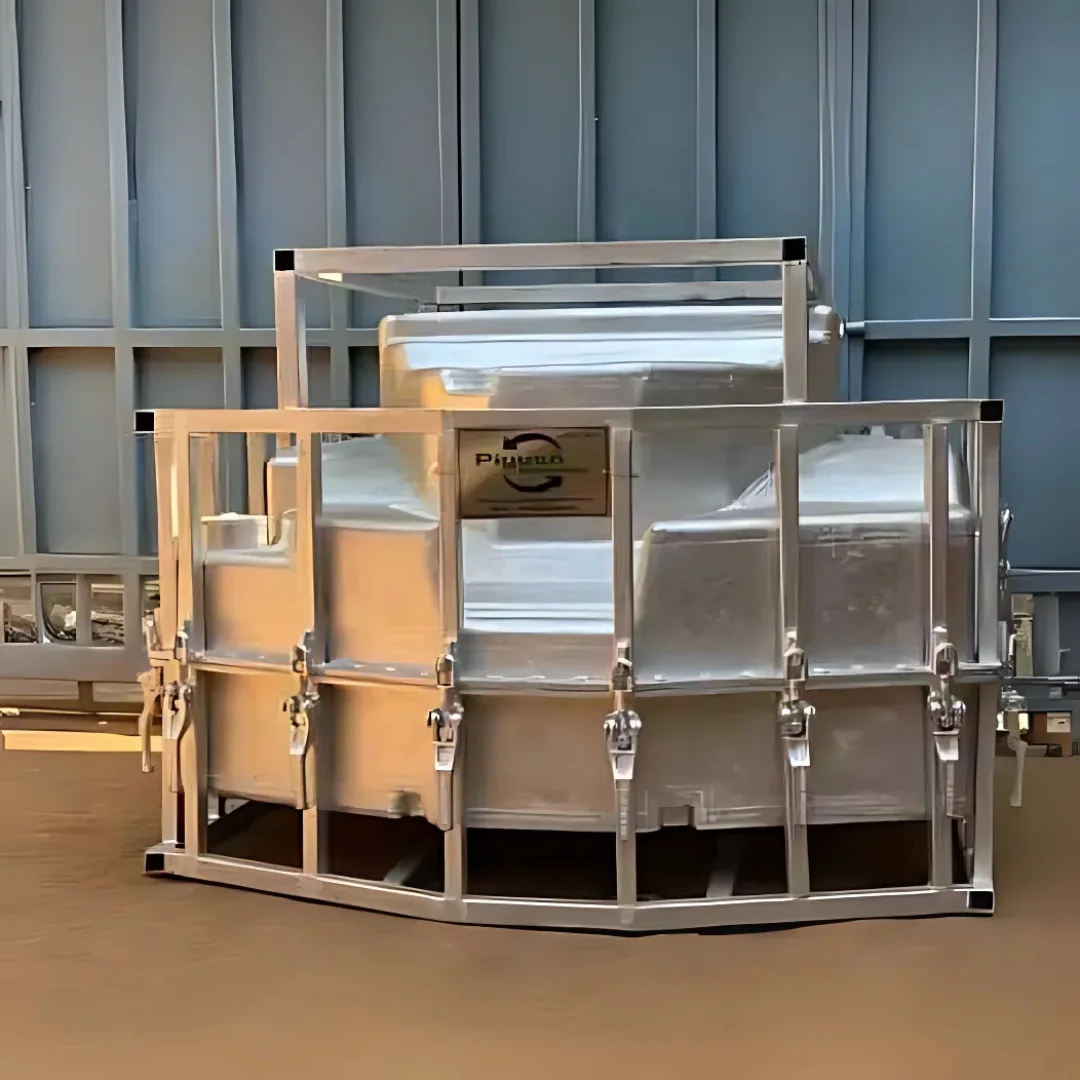

Making these moulds takes careful planning, skilled hands, and the right tools. Our expert team uses advanced machines and design software to make sure every mould is accurate and of high quality.

Though the process can take time depending on the design, sheet metal moulds are a smart choice they’re tough, dependable, and suitable for many manufacturing uses.

How is Piyush Rotomac different?

With over 30 years in the industry, we’ve brought in many innovations from smart product designs to using the latest technologies. Our goal has always been to deliver reliable solutions, both in India and around the world.

Experience, Expertise, Excellence

Young and Highly

Qualified

As Per Industry

Standards

Successful Realized

Since 1990

ROTOMOLD PROCESS

Designing is the first and most important step in the Roto moulding process. Our design team begins by understanding your product needs including shape, quality, and appearance. Based on your requirements, we plan and create the mould design carefully.

If you already have a technical drawing or design, you can share it with us. Once the design is ready, we send it to you for feedback and approval. After your approval, the project moves to our technical team for the next stage.

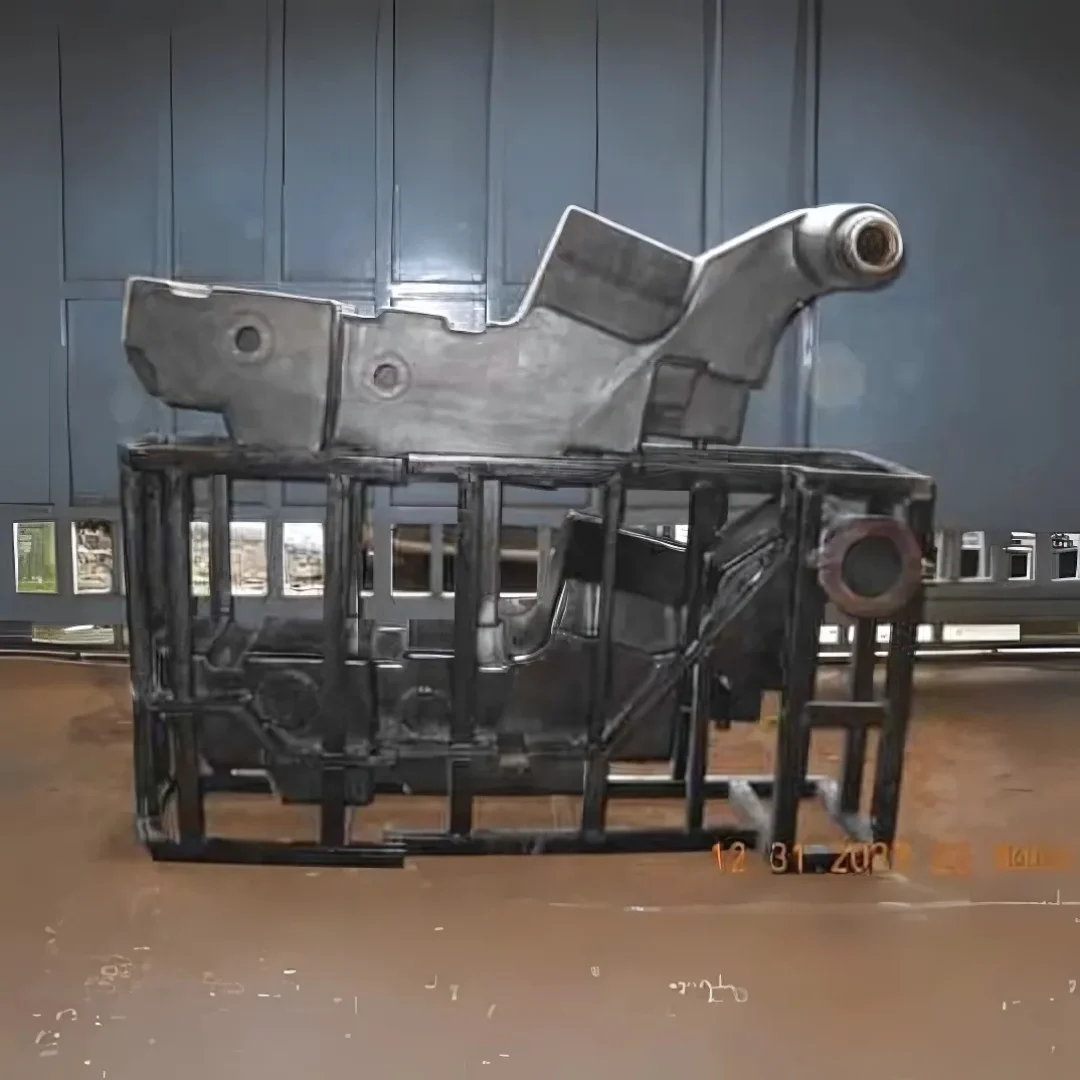

Once the design is approved, our technical team takes over. The project head reviews the design and decides the best way to move forward with manufacturing.

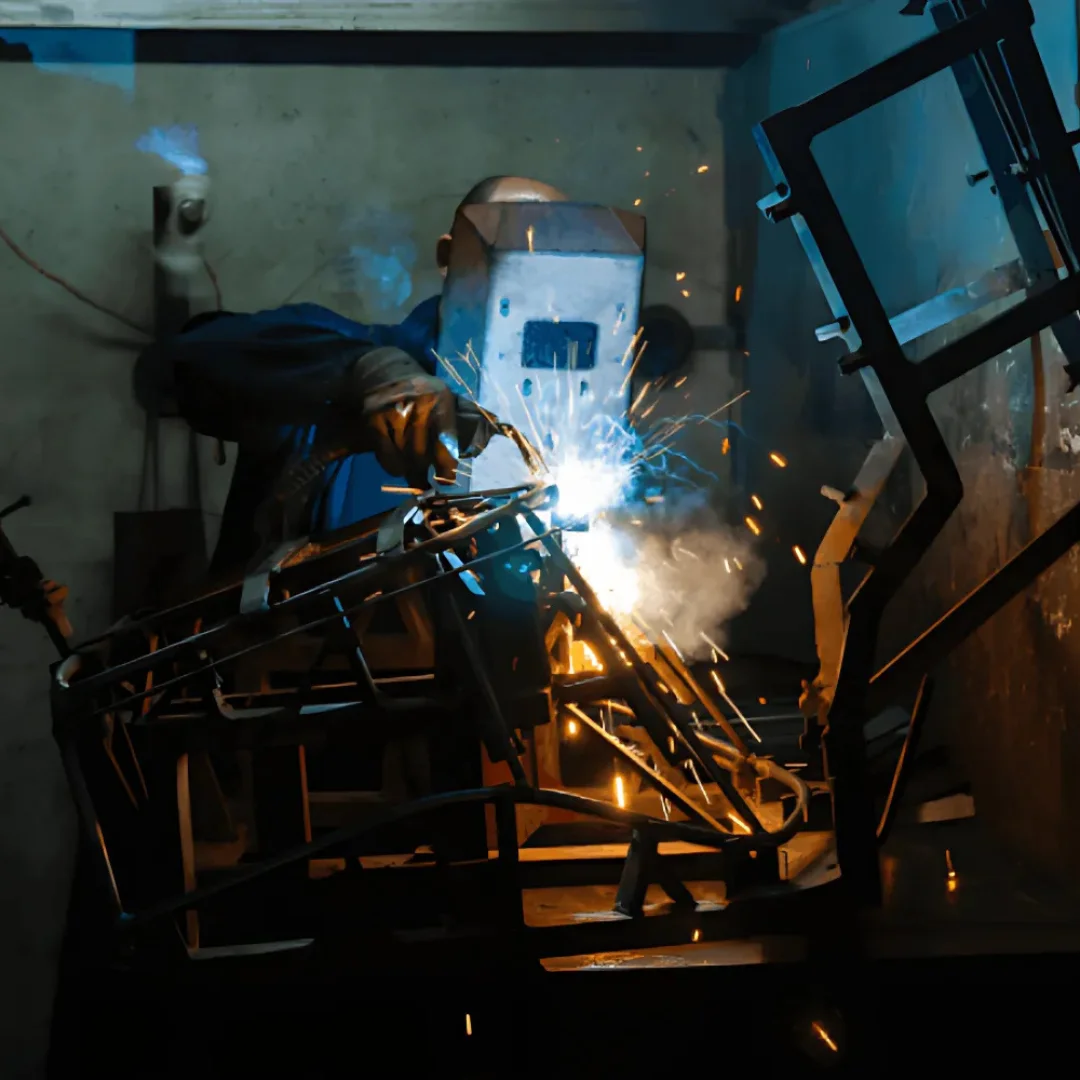

Our skilled engineers and trained workers use top-quality materials and advanced machines to build the mould. We work with both stainless steel (SS) and mild steel (MS), and use CNC and VMC machining where needed to ensure precision.

The manufacturing process takes time, but that’s because we focus on getting every detail right so the final mould is strong, accurate, and long-lasting.

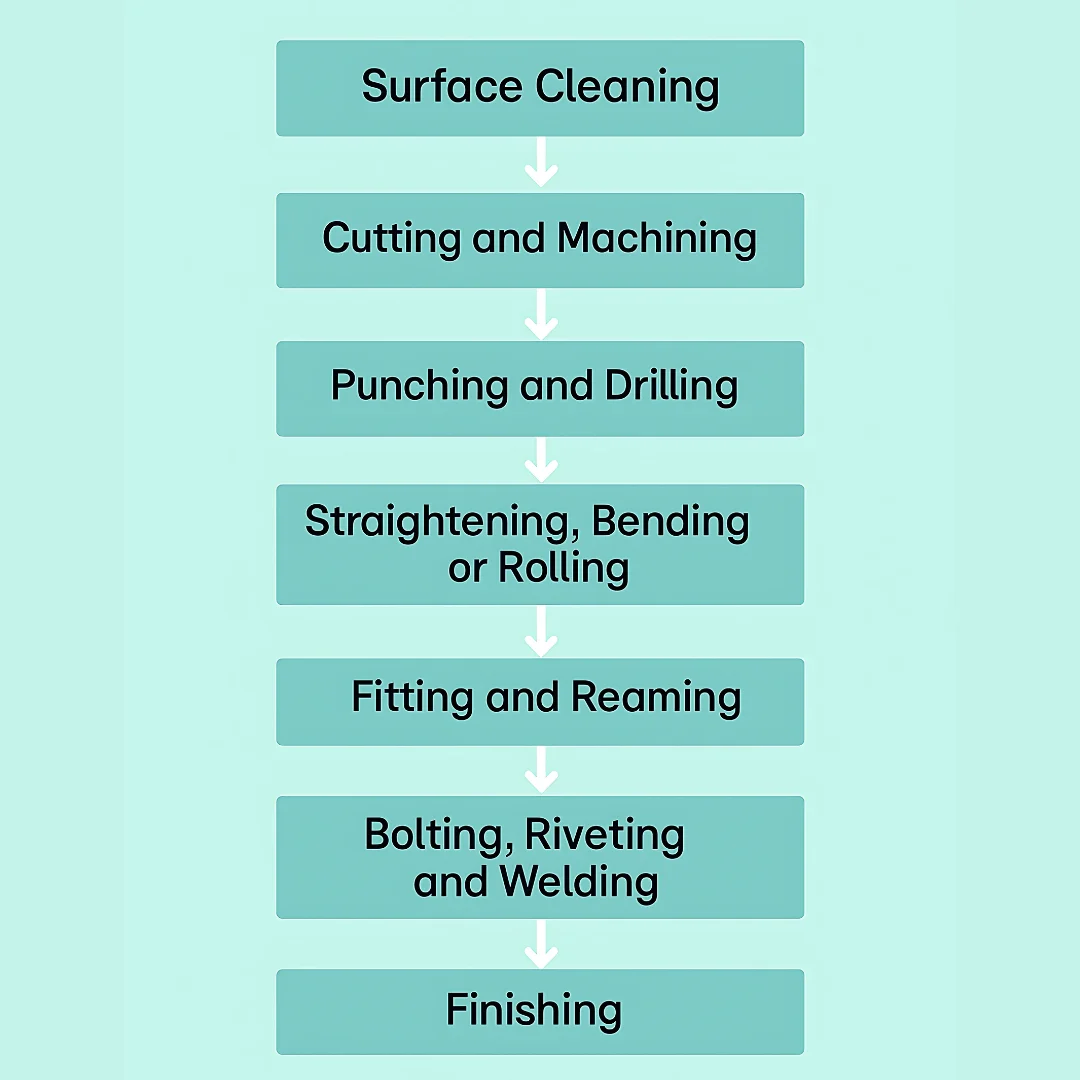

The step-by-step process in Piyush Rotomac

During the manufacturing process, we pay close attention to every small detail. This focus is what helps us deliver moulds and machines that meet the highest quality standards.

For parts with complex shapes and exact dimensions, we use precise milling techniques on steel. These milled parts are then carefully welded together to complete the mould with strength and accuracy.

Piyush Rotomac is based in one of India’s largest industrial zones a location that helps us stay connected and efficient. From here, we ship our finished moulds and machines across the world, with regular deliveries to North & South America, Asia, Europe, and beyond.

One reason our clients have stayed with us for years is the way we support them. We don’t charge extra for storing or maintaining moulds. In fact, our facility is designed to keep serving clients better, every single day.

Industries We Serve

At Piyush Atomac, our high-performance machines are trusted across a wide range of industries. From flexible packaging to printing and labeling, we deliver customized solutions that enhance productivity, ensure precision, and support scalable growth.

Connect With Piyush Rotomac

We’re here to help! Whether you have questions about our products or need support, our team is ready to assist you. Reach out today

Our Clients